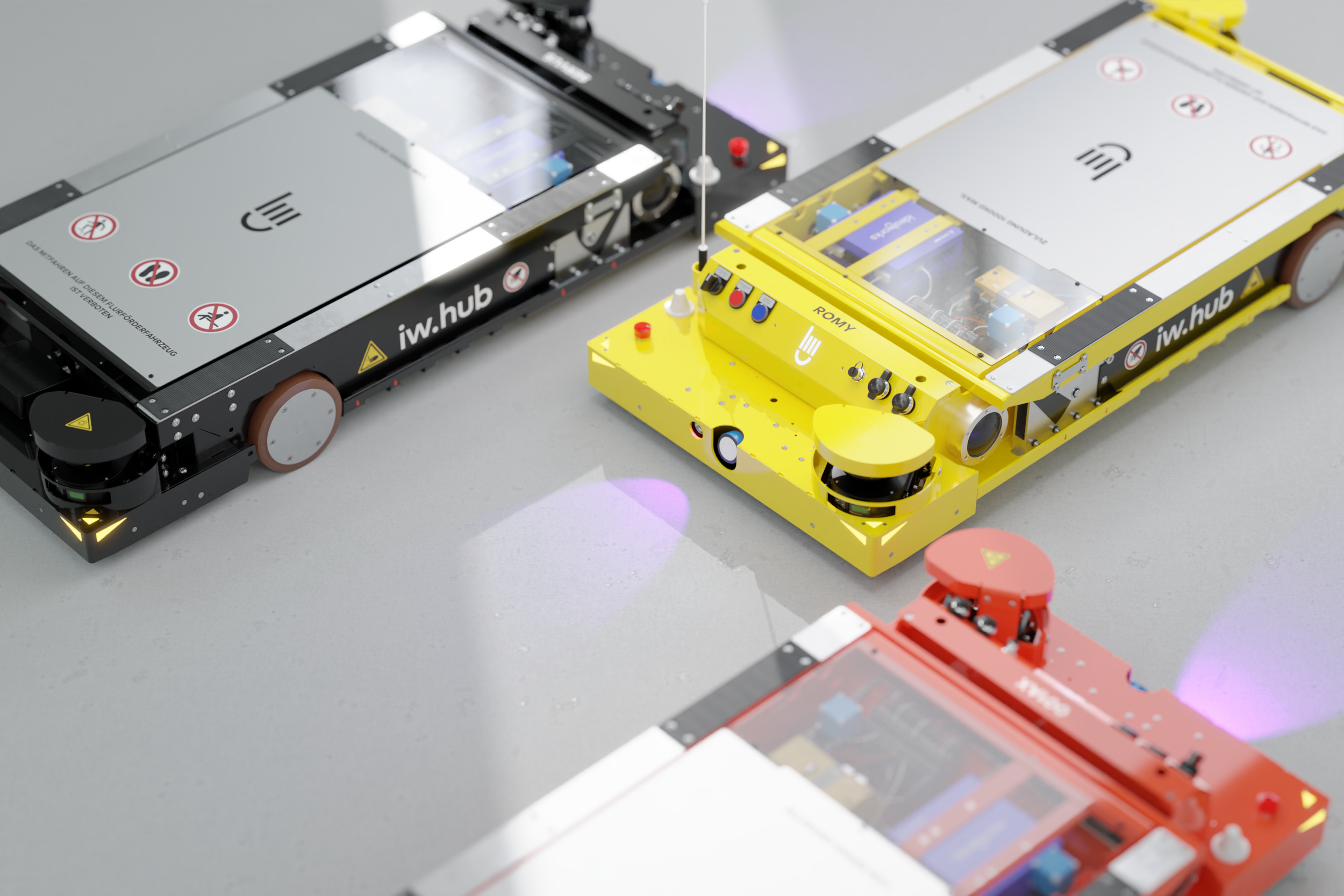

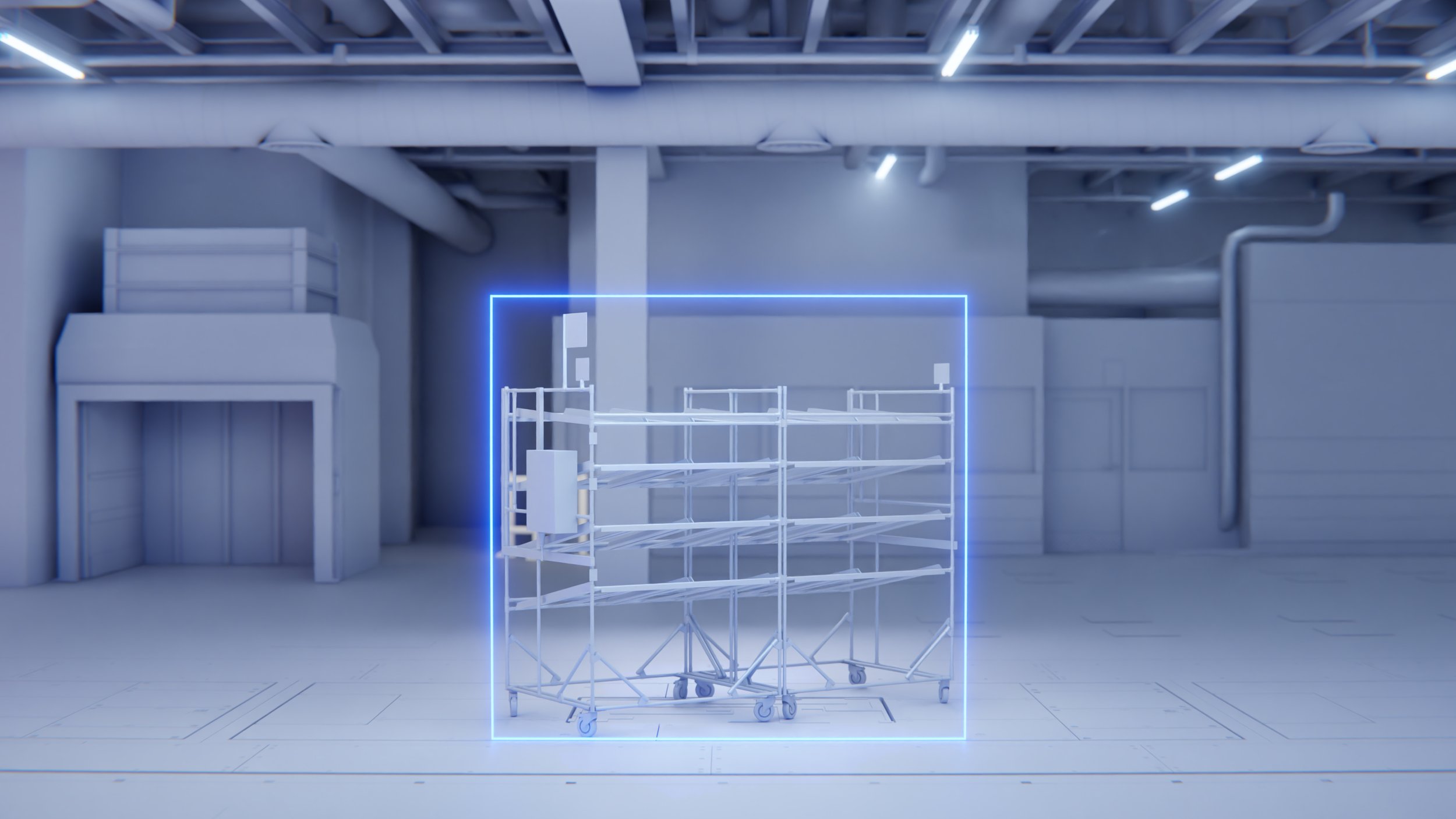

SPECIAL PROJECTS

Advanced design projects and support for BMW Group teams around the globe

ADVANCING CUTTING-EDGE TECHNOLOGIES

The BMW Group + QUT Design Academy Special Projects program is for professional design graduates to work on advanced R+D projects for real-world applications. These projects are established by BMW Group in Germany or the UK, and are supported by the team of Design Associates at the Academy.